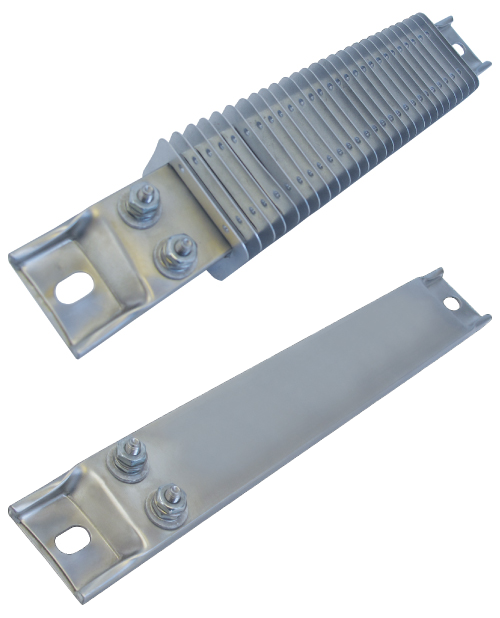

Channel Strip Heaters

Bucan channel strip heaters are reliable flat heating cells, designed to provide efficient heat to flat surfaces and in space heating applications. The thick rectangular stainless housing of these heaters provides a rugged construction suitable for industrial applications. Finned channel strip heaters have relatively larger exposed surfaces compared to regular channel heaters. This makes them highly efficient in transferring heat in both natural and forced convection space heating.

The housing of a channel strip heater is 0.375” x 1.5” stainless steel rectangular tubing. Coiled Nickel-Chrome wire is placed inside special ceramic tiles. The terminals are secured with ceramic and mica insulators to the sheath. In order to improve their heat transferring capability and to make them vibration-resistant, channel strip heaters are filled with magnesium oxide powder that is compacted through vibration. Channel strip heaters are made with or without slotted mounting tabs.

Finned channel strip heaters utilize 2” x 1.375” Aluminized steel fins (Stainless steel optional) that are designed in such a way that they grip the channel heater housing and dissipate heat efficiently.

Typical Heating Applications:

- Hot Plates

- Space Heating

- Ovens

- Molds

- Pre-Heaters

- Sealing Bars

- Load Bank Resistors

Channel Strip Heaters

- Max Sheath Temp: 1200°F

- Standard Voltage: 120 or 240 Volts (other voltages are available; consult the factory)

- Max Amps: 20 A

- Watt Density (nominal): 20 w/in2

- Wattage Tolerance: +5%, -10%

Finned Channel Strip Heaters

- Max Sheath Temp: 1200°F

- Standard Voltage: 120 or 240 Volts (other voltages are available; consult the factory)

- Max Amps: 20 A

- Watt Density in still air

- Up to 250°F: 20 w/in2

- 250°F - 500°F: 15 w/in2

- 500°F - 750°F: 10 w/in2

- Watt Density 10ft/sec moving air

- Up to 200°F: 38 w/in2

- 200°F - 350°F: 30 w/in2

- 350°F - 500°F: 20 w/in2

(for other air velocity/temp. combinations consult the factory)

- Wattage Tolerance: +5%, -10%

Channel Strip Heaters

BA style with mounting tabs

BA style without mounting tabs

BC style with mounting tabs

BC style without mounting tabs

BD style with mounting tabs

BD style without mounting tabs

Finned Channel Strip Heaters

FBA Style

FBC Style

FBD Style

Installation Tips

- It is critical to have a good surface-to-surface contact between channel strip heaters and mounting surfaces. These surfaces should be clean, flat and smooth.

- Channel strip heaters expand when energized and thus tend to get detached from the surfaces they are mounted on. To prevent this, it is essential to allow room for expansion by tightening firmly the mounting screw on one end (usually the terminal side) and leaving the other side slightly loose. When relatively long strip heaters are used, it is good practice to use clamps to hold strip heaters firmly attached to application surfaces.

- While tightening post terminals (30 in - lbs), a backup wrench should be used to hold the counter-nut to ensure tightness and prevent terminals from damage.

- When a finned channel strip heater is placed in an air stream, the air flow should be perpendicular to the length of the heater and parallel to its width (1.5” side).

- Channel strip heaters (with or without fins) that operate at a potential difference of more than 300V between their line voltage and the ground, should be isolated from the surface of an application by secondary isolating ceramic bushings. Bucan offers insulators that are adequate for Ø 1/4” screws.

To be able to use these ceramic insulators, strip heaters should have 1/2” x 5/8” mounting slots (factory pre-punched upon request).

BA style with mounting tabs

BD STYLE WITH MOUNTING TABS

FBA STYLE

For specifications, please check product catalogue

Download PDF