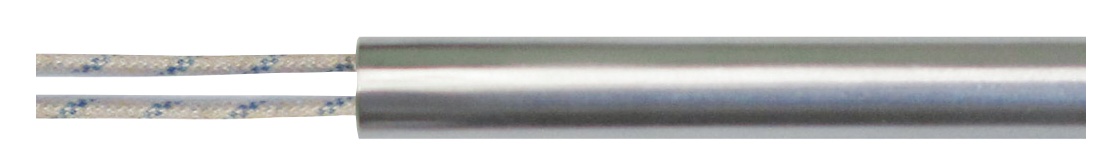

High Density Cartridge Heaters

Cartridge Heater

Bucan manufactures high-density cartridge heaters for industrial use.

Our superior quality, high-temperature cartridge heater has applications in plastic moulding, packaging equipment, labelling machinery, food production, semiconductors, medical devices, plastic welding, etc.

Bucan cartridge heating elements are custom-made to suit the unique needs of every application. You can select from different termination styles, mounting attachments, and materials to suit your industrial needs.

For regulating temperature, we also manufacture temperature controllers and sensors for cartridge heaters.

Specifications

We have placed the resistance wire as close to the outside shell as possible. The MgO powder insulation around the loops is compacted by swaging, which makes the heat transmission very efficient. Our high-density cartridge heater can have up to 200 w/in2 watt densities.

We usually supply our cartridge heater with lead wires. The attachment of the leads to the pins is done internally, in a 3/8" cold section.

To facilitate installation and avoid excessive air pockets, we make the cartridges 0.004" smaller than the nominal size of the receptacle hole, with a tolerance of +/-0.002".

Bucan cartridges can be dual-voltage, three-phase, and/or supplied with ground terminals.

High-Density Cartridge Heater for Every Industry

Bucan's engineers know that every system requires a different type of heating element. Crucial factors such as temperature, humidity, physical environment, the system in use, and your budget will determine the choice of materials.

When supplying you with cartridge heating elements, we take care of the following factors:

1. The Physical Environment For Cartridge Heater

Our cartridge heaters are designed to work harmoniously with the physical environment of your industry. Special attention is paid to making the cartridge heater leak-proof so that it does not damage surrounding material.

2. The Required Temperature For Cartridge Heater

We use suitable sheathing material that withstands exposure to high temperatures. The use of the right materials increases the longevity of the heater and reduces maintenance.

3. Energy Efficiency Cartridge Heater

Certain materials have high conductivity and require less power to heat. These save time, money, and energy. You can consult us when selecting the materials that offer the highest energy efficiency.

4. Size For Cartridge Heater

Bucan can provide you with the right-sized cartridge heating element for your industrial needs.

Refer to the specifications section to see the whole catalogue of our cartridge heater based on size.

5. Watt Density For Cartridge Heater

We offer a full range of high-density cartridge heaters based on watt density to fit your specific needs.

Accessories and Optional Features of Cartridge Heater

We offer accessories and optional features to increase the functionality of our cartridge heating elements.

For secure mounting, we offer two types of mounting attachments:

- FL Style

- IM Style

The FL-style mounting will secure the cartridge heater firmly in place in a place where there is excessive vibration. The IM Style mounting allows for simultaneous threading and sealing.

We also offer additional features, including:

- Build-in thermocouple

- Graphite coating

- Moisture- and contamination-resistant seals

- Distributed wattage

- Centre-less grinding

- Zones and cold sections.

Contact Us Today

Bucan can manufacture custom-made high-density cartridge heaters suited to your application’s specific needs.

With our on-site design and manufacturing facility, we can accurately assess your needs and supply you with heating cartridges made of the ideal material to suit your needs.

Call us at 1-855-282-8226 or fill out this form.

Applications Of Cartridge Heater

- PLASTIC MOLDINGS

- PACKAGING EQUIPMENT

- HEATING TANKS

- PLASTIC EXTRUDERS

- LABELLING MACHINERY

- AIR AND LIQUID HEATING

Specifications Of Cartridge Heater

| DIAMETER (NOM) | 1/4" | 5/16" | 3/8" | 1/2" | 5/8" | 3/4" | 1" |

| DIAMETER (ACTUAL) | 0.246 | 0.310 | 0.371 | 0.496 | 0.621 | 0.746 | 0.996 |

| MAX LENGTH | 36" | 36" | 72" | 96" | 96" | 96" | 96" |

| MAX VOLTAGE CSA | 240V | 240V | 480V | 480V | 480V | 480V | 480V |

| MAX VOLTAGE | 250V | 250V | 600V | 600V | 600V | 600V | 600V |

| MAX WATTS AT 240V | 1200W | 1300W | 2000W | 3000W | 5300W | 5300W | 5300W |

| WATTAGE TOLERANCE | +5% -10% | ||||||

| DIAMETER TOLERANCE | +/- 0.002" | ||||||

| LENGTH TOLERANCE | +/-2% OF LENGTH | ||||||

| CAMBER TOLERANCE | 0.010" PER FT UP TO 12" | ||||||

| 0.018" PER FT ABOVE 12" | |||||||

SELECTION & INSTALLATION OF CARTRIDGES HEATERS

- Cartridges heaters should have a tight fit in the receptacle hole. Drilling and reaming to the next standard size and using a larger cartridge could solve the problem of loose or worn-out holes.

- Lead wires should be kept away from abrasion and should not be exposed to temperatures above 840°F.

- Stocked cartridge heater, which have been exposed to air and moisture for a long period of time, should be energized at a low voltage prior to usage, in order to eliminate possible moisture contamination. It is always preferable to stock cartridges in sealed bags.

- Cartridges should be immersed completely inside the receptacle hole. Proper mounting attachments can prevent their edging out by vibration. If it is necessary to have an exposed section, that part should be unheated

- Receptacle holes should be properly cleaned prior to the installation of a cartridge.

- When designing molds, it is recommended to make the receptacle cavities such that they will accommodate the cartridge heater completely and all-the-way-through. This will later facilitate the removal of the heaters.

- Watt densities should be kept within the safe range. This can be done by using either larger cartridges or as many as it is reasonably possible.

- To prevent short cycling, the wattage of a cartridge heater should be close to the required application wattage.

Mounting Attachments

FL Style

Flange mounting attachments secure the cartridge firmly in place in applications where there is excessive vibration. 1 ½”diameter is the standard flange size. Flanges with smaller diameters are generally used as stop rings. |

IM Style

|

Electrical Terminations

High Temperature Leads externally connectedA1 StyleHigh temperature (840°F) fiberglass insulated leads are connected externally to the two solid pins exiting from the cartridge. A silicone impregnated fiberglass jacket insulates the connection. |

High Temperature Leads internally connectedA2 StyleTo provide flexibility at the lead end, high temperature (840°F) leads are connected to the solid pins inside the cartridge. |

High Temperature leads connected at 90 degrees angleA3 StyleA bracket having the same diameter as the cartridge provides a 90° exit to the fiberglass insulated high temperature leads. The bracket is potted with high temperature cement (480°F). |

Stainless Steel leads connected at 90 degrees angleK2 Style

|

Stainless Steel braided leads connected straightK1 StyleHigh temperature leads (840°F), with flexible abrasion resistant stainless steel braid exit straight from a cartridge. An additional 1/4” cold section from the immersed length is allocated to accommodate the stainless steel jacket. |

Teflon insulated leads connected straightTF StyleInternally connected Teflon leads (480°F), with Teflon plugs, protect the cartridge from contamination. High temperature black epoxy or silicone RTV seals are available too. A minimum cold section of 1” at the lead end is necessary to protect the Teflon leads from high temperature. |

Armor Cable Stainless Steel leads connected straightX1 StyleHigh temperature (840°F) lead wires with abrasion and contamination resistant armor cable protection exit straight from a cartridge heater. The armor cable is crimped to the cartridge (brazing is available upon request). In order to accommodate the armor cable, an additional 1/4” cold section is allocated at the lead end. |

Screw TerminalsPT StyleFor high temperature applications, screw terminals (#10-32 is standard, other sizes are available) are silver-brazed to the extended solid pins of a cartridge. This type of terminal is not recommended for cartridges having less than 1/2” diameter |

Armor Cable Stainless Steel leads connected at 90 degrees with Copper elbowX3 StyleArmor cables are less flexible than stainless steel braid, but provide contamination resistance in addition to superior protection against abrasion. A copper elbow, brazed to the cartridge externally, provides a 90° transfer. |

Armor Cable Stainless Steel leads connected at 90 degrees angleX2 StyleProtective armor cable, which is silver brazed to the side of a low profile stainless steel bracket, provides right-angle transfer to the high temperature leads when space is limited and elbows cannot be used. |

90° bracket and elbow heights

| Cartridge OD | Bracket | Elbow |

| 1/4" | 3/8" | 7/8" |

| 5/16" | 3/8" | 1" |

| 3/8" | 3/8" | 1" |

| 1/2" | 1/2" | 1 3/16" |

| 5/8" | 5/8" | 1 3/8" |

| 3/4" | 5/8" | 2" |

Operating temperature versus actual temperature of the cartridge heater?

Bucan cartridge heater are designed to withstand a sheath temperature of up to 1500°F. The recommended maximum operating temperatures for many applications are much less than that. There are many factors that have a direct effect on the lag between the actual sheath temperature of a cartridge heater and the monitored temperature of the surrounding material during the heat-up cycle. In some cases, this temperature lag is so significant that the cartridge will reach its elevated critical temperature even when the surrounding material is monitored to have a relatively much lower temperature level. The most common factors that contribute to the degree of temperature difference are the following:

- Thermal conductivity of the material being heated

- The cartridge sheath watt density

- The tightness of the cartridge inside the hole

- The location of the monitoring sensor

- The alloy of the cartridge sheath material

- Contamination around the cartridge heater

These factors should be taken into consideration while selecting a cartridge for a specific application. One common practice is to use stainless steel cartridge sheathes for temperatures up to 1000°F and Incoloy sheathes for temperatures up to 1400°F. Another design consideration related to the operating temperature is the electrical termination of a cartridge. Teflon and TGGT leads have 480°F rating while MGT wires can withstand up to 840°F. When cartridges are used at relatively high temperatures, the terminals selected should be either different than the common high-temperature lead wires; or the design should be such that the temperature around the lead wires (whether the leads are connected internally or externally to the cartridge heater) is maintained at a temperature level lower than the critical temperature limit of the lead wire.

Built-in thermocouples

One optional feature on Bucan cartridges is built-in thermocouples. These could be type "J" or "K", grounded or ungrounded, and attached either at the disc end or the middle of the cartridge.

Graphite coating

To facilitate their installation and removal, cartridges can be coated with a graphite-like substance. This solid lubricant does not increase the outside diameter and is suitable for temperatures up to 750°F.

Moisture and contamination-resisting seals

To protect cartridge heater against moisture and contamination, Teflon lead wires with Teflon seals are used. Epoxy (250°F) or RTV (450°F) silicone seals are alternative contamination and moisture-resisting barriers.

Distributed wattage

In applications such as sealing bars or rubber molds, the two ends of a cartridge heater are usually colder than the middle. To overcome this inconsistency and have a uniformly distributed heat source, cartridges could be made to have higher wattages at the ends. 35/30/35 is a common wattage distribution.

Center-less grinding

In applications where superior heat transfer is required, the tolerance on the outside diameter could be improved to +/-0.001" by center-less grinding.

Zones and cold sections

We can also manufacture cartridges with cold sections and separate zones that can be controlled independently.