Mica Strip Heaters

Mica insulated strip heaters are economical heat sources, suitable for providing heat to flat surfaces. The sheath temperature is limited to 900°F. Maximum allowable watt densities with respect to application temperatures are shown in the diagram. However, for temperatures below 500°F, 20 Watts/in² is a safe value.

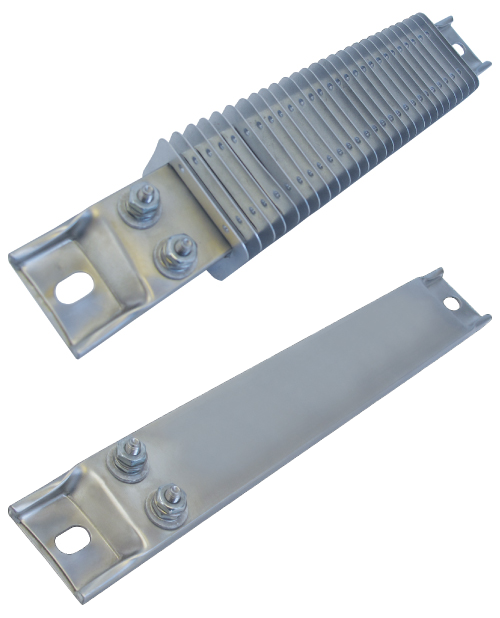

In order to secure efficient heat transfer and avoid thermal expansion issues that detach strip heaters from the surfaces that they are applied to, strip heaters can be made to include several mounting holes or pressure plates that provide rigidity and improve heat transfer uniformity.

Mica insulated strip heaters are available in many electrical termination styles, and within certain design limitations can accommodate holes and cut-outs.

Typical Heating Applications:

- Packaging & Sealing Machines

- Food Tables & Warming Equipment

- Plastic Extruders

- Blow-Molding Machines

- Ovens, Hot Plates

- Incubators

- Vulcanizing Tablets

| Max Sheath Temp | 900°F |

| Max Voltage | 600V |

| Max Amps | 25 Amps |

| Max Safe Watt Density | 20 w/in2 |

| Wattage Tolerance | +5%, -10% |

| Approx. Thickness | 3/16" |

| Min. Width | 3/4" |

| Length Tolerance Up to 18" Over 18" |

+/- 1/16" +/- 1/8" |

| Width Tolerance | +/- 1/16" |

| Top Sheet Bottom Sheet |

Stainless Steel 430 Aluminized Steel |

Screw Terminals

Screws are the most commonly used terminals on strip heaters. They are recommended for high amperages (max 25 Amps). 10-32 screws are standard. Other sizes are available.

A Style

B1 Style

B2 Style

To avoid internal damages, screws should not be tightened excessively (30 in-lbs). It is good practice to use a backup wrench on the lower nut for counter-torque.

G Style

Terminal boxes eliminate the risk of electric shocks and shorts by enclosing the terminals in a heavy-duty stainless-steel box. These boxes come in two styles, G1 and G2. For three-phase and dual voltage applications, special boxes are used.

| W x L x H (in) | |

| G1 | 1 5/8" x 2" x 1 5/8" |

| G2 | 2" x 2 1/4" x 1 3/4" |

V Style

Ceramic terminal covers provide a cost-effective way to avoid electric shocks and shorts. These covers require 1" long screws.

Lead Wire Terminals

Internally connected high-temperature lead wires provide a safer electrical connection. However, it is physically impossible to conceal heavy gauge wire under the top metallic sheet. This limits the maximum amperage applicable to 20 Amps.

L Style

LF Style

J Style

JF Style

Single or double ended mica insulated high temperture wire with or without SS braids.

H Style

Straight armor cable provides excellent protection against abrasion and contamination. Sharp bending is not possible with this type of lead.

GM Style

Armor cable with a 90° elbow (which can have any orientation) is for applications where height restrictions make straight armor cable exits unsuitable.

E Style

Stainless steel braids provide strength and protect leads from abrasion. Moreover, sharp bends are possible with this type of lead.

European Plugs

High-temperature European plugs eliminate all possible exposure to live connectors. They are ideal in applications where the electrical termination gets disconnected frequently.

K00

K45

Holes and Cut-outs

Mounting slots, holes and cut-outs can be incorporated into the design of mica strip heaters. However, there design limitations considered and the should be consulted prior to placing any order.

Special Constructions

Mica strip heaters are versatile and can be made into any irregular shape (within design limitations). They can also be multi-sided; “L” shaped, “U” shaped or rectangular. It should be noted that for efficient heat transfer, multi-sided strip heaters should be backed with pressure plates.